Why is it such a big deal if robots can make whole garments?

Apparel manufacturers are in trouble. The world is running out of resources and cheap labor is no different. With 65 Million workers it’s not a small labor pool, but rising labor wages, tighter immigration policy and worker migration to service jobs is taking the one competitive advantage that manufacturers bring to brands.

What labor is left will be greatly impacted by automation. The International Labour Organization (ILO) reports that robots will replace 64% of textile/clothing and footwear workers in Indonesia, 86% in Vietnam and 88% in Cambodia.

Today fashion brands support deflation with cheap labor. When that runs out, do we just watch prices rise?

We don’t need robots to signal panic. With the cost of labor rising globally, every process is already under attack from automation. Each step big or small that a manufacturer takes puts his competitor one step behind.

The solution isn’t always robotics. Integration, lean and transparency are 3 core components regardless of the solution. These can lead to simple steps like better line balancing and semi-automation that will dramatically increase productivity and deskill the production line.

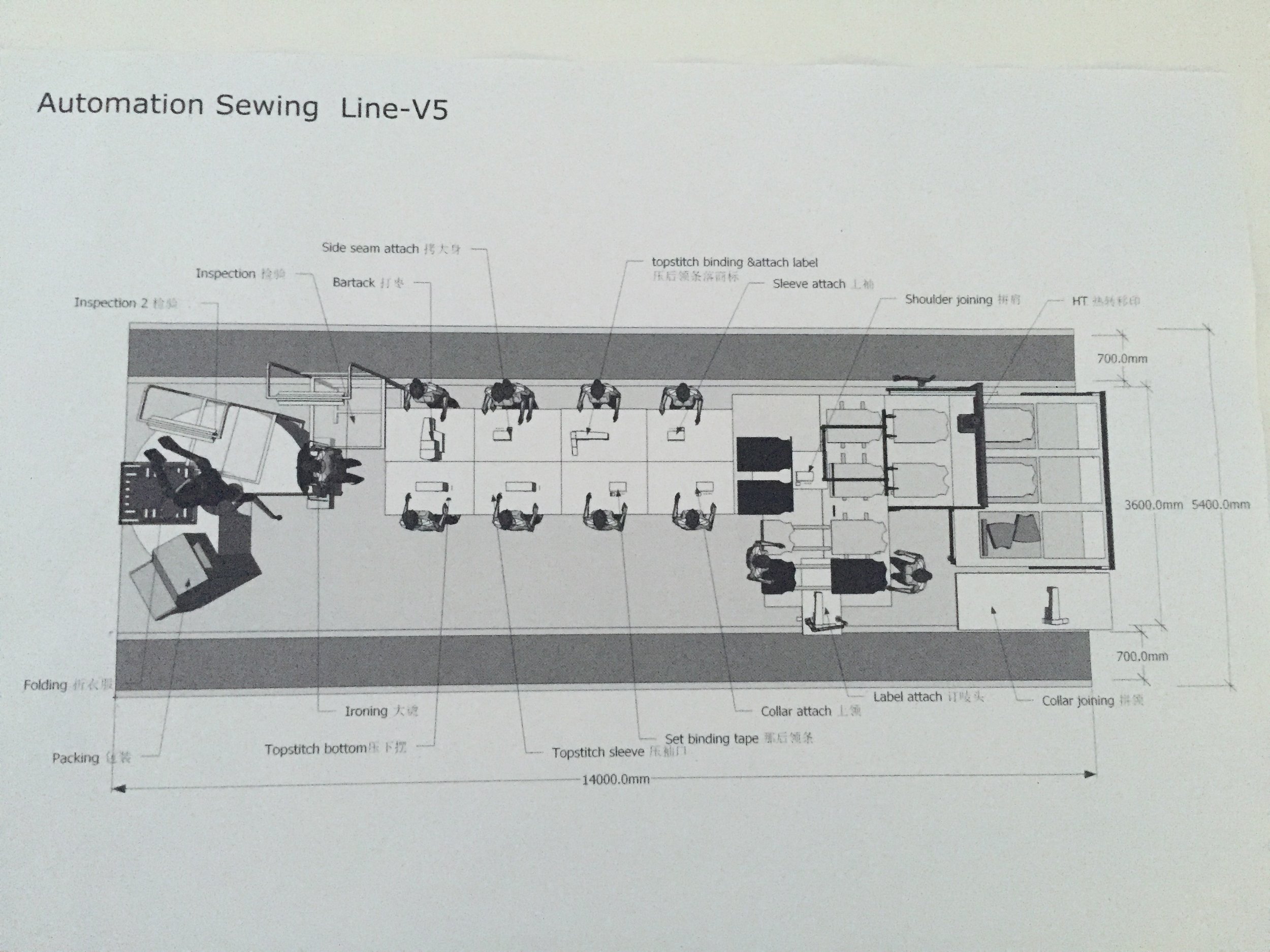

In the pictures above, the manufacturer goes from a workline of 18 operators using single piece flow to a workline with 11 people. A 40 percent reduction with a rebalanced line and two areas of automation.

So why hasn’t it already been done?

The abundance of labor and the interconnected nature of handling the material made it easier in the past to ignore/avoid novel solutions. However, as the cost of labor rises, automation can be introduced in more and more places. As it does, the old technologies make more sense in combination then they did as individual automations. Suddenly, you go from no automation to mass automation.

What is your plan?

Ultimately, your take on the question, “what is your plan?” greatly depends on what your labor cost is. If it is below $400/mo you still have a few years (Bangladesh, Ethopia, Kenya). If your labor cost is above $400/mo, you are reaching the break even point for automation. You don’t have much time to stay competitive.

SIgn up for my newsletter

Nowhere is the battle for the future of work so clear and dramatic as the apparel industry. Pete is at ground zero in this dramatic change watching it play out in real time. Pete is an excellent choice to help any organization understand the coming wave of automation, its impact and what to do to grow jobs and productivity.

Kelly Drennan - Sustainable Fashion Expert | Systems Thinker | Collaborator | Circular Economy | Non Profit Founder | Producer of WEAR